Project Name: Guangdong Yingde Farm Fattening House Pig Farm Steel Structure Project

Project address: Yingde City, Guangdong Province

Engineering category: Light steel structure turnkey project (design, processing, construction)

Building area: Two story building area of approximately 46000m2

Scope of Engineering Contracting: Modern Livestock Steel Structure

Construction Execution Standards:

1. Code for Seismic Design of Buildings (GB 50011-2010) (2016 edition)

2. Code for Load of Building Structures (GB 50009-2012)

3. Design Standard for Steel Structures (GB50017-2017)

4. Technical Code for Cold formed Thin walled Steel Structures (GB 50018-2002)

5. Technical Code for Steel Structure of Light duty Buildings with Portal Steel Frame (GB 50022-2015)

6. Code for Design of Concrete Structures (GB 50010-2010)

7. Code for Construction of Steel Structures (GB 50755-2012)

8. Standard for Acceptance of Construction Quality of Steel Structures (GB 50205-2020)

9. Unified Standard for Construction Quality Acceptance of Building Engineering (GB 50300-2013)

10. Engineering drawings and related materials;

11. Strictly follow the design requirements and relevant specifications for construction, ensuring the quality of production and installation.

With the perfect completion of the steel structure project of the Guangdong Yingde Education Feishe Pig Farm, we present you with a detailed completion report. In this issue, we will take you to appreciate the charm of steel structure engineering and explore the stories behind it.

The project is designed with the concept of "safety, practicality, and aesthetics", perfectly combining modern pig farm building styles with green environmental protection concepts to create a standardized pig farm with high standards, high quality, and high requirements (three highs); The single story building area of the project is approximately 23000 square meters, with a total of two floors of approximately 46000 square meters; It consists of 2 six story buildings, 1 four story building, 2 double story buildings, and 1 single story building. Since the start of construction on July 18, 2023, after three months of intense construction, the steel structure project has been completed as scheduled. During this period, we strictly controlled each link to ensure the quality and progress of the project.

Civilized construction is not only a standard, but also an attitude. Let us work together to achieve civilization, safety, and humanization on construction sites, and contribute to creating a better livestock industry.

Develop a scientific construction plan and scheme before construction, clarify the work tasks and responsible persons of each link, ensure the orderly progress of construction, and equip qualified safety facilities and protective equipment to ensure the safety of personnel. At the same time, strengthen personnel safety education and training, improve personnel safety awareness and self-protection ability.

Daily morning meetings for the project

After the materials arrive at the site, on-site personnel need to check whether the materials meet the standards according to the contract disclosure requirements, and confirm that they are correct before they can be stored in the warehouse; The incoming materials should be classified and neatly arranged.

Material thickness detection chart

From pre embedded installation to installation of primary and secondary structures, strict adherence to the "Code for Construction and Acceptance of Steel Structures" GB50205-2020 edition is required.

Galvanized content detection diagram for purlins

Installation diagram of embedded parts

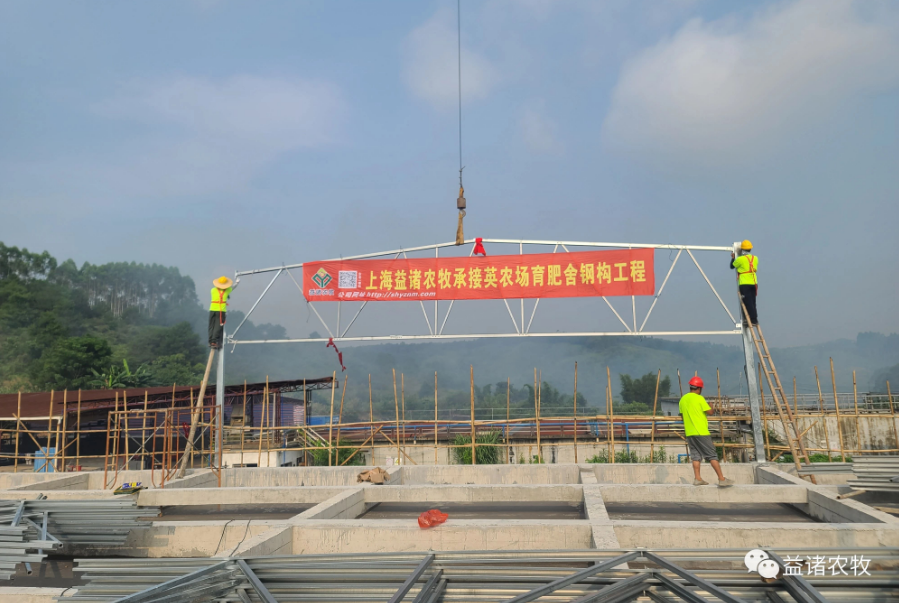

Effect diagram of truss hoisting

Installation rendering of roof purlins

Finished product rendering of hoisting substructure installation

The main structure of this project adopts our company's 3.0 structural form, which is more convenient to install than the 2.0 mode, with faster response speed, greatly improving installation efficiency, and laying a solid foundation for timely completion! At the same time, it also outperforms the previous 2.0 in terms of employment, saving costs for customers. The installation of the primary and secondary structures requires horizontal and vertical alignment. The bolts at the joint bolts should be tightened and checked repeatedly by multiple people to confirm that they are qualified before starting to install the enclosure structure.

Completion rendering of roof panel installation

The roof adopts 490 type 360 ° interlocking panels, with single slope and no overlap. Except for the ridge and eaves, there are no nail holes in other positions, ensuring the integrity of the roof and greatly reducing the risk of water leakage.

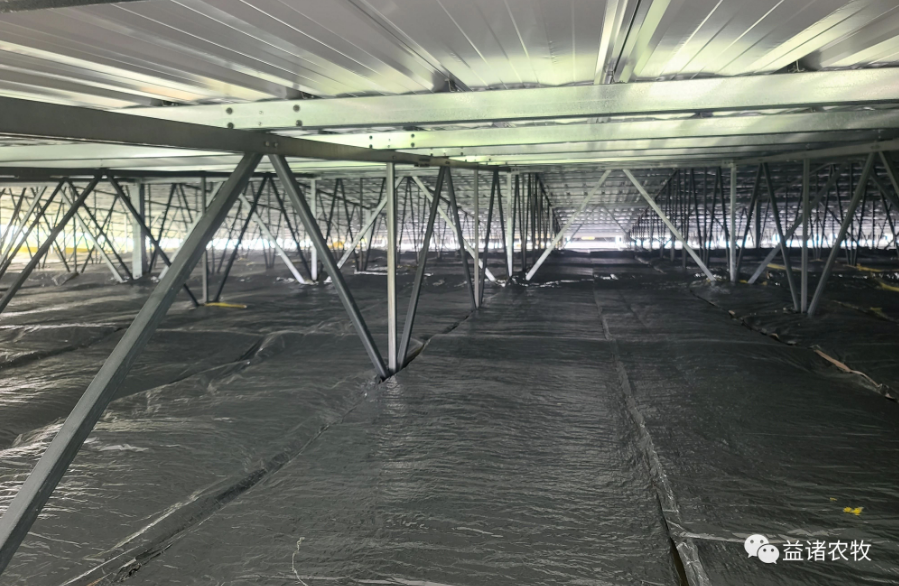

Ceiling insulation cotton laying completed rendering

Installation rendering of corridor wall

Corridor ceiling installation completed rendering

Ceiling panel installation completion rendering

The enclosure structure is the most critical test of construction level. Only after each step is completed and accepted can the next step be carried out. Each step must follow the design drawings for construction, and based on the actual situation on site, develop the best construction plan that meets the site requirements. While considering quality, shorten the construction period.

Aerial completion rendering